News

Introducing Rolex’s All New 2020 Submariner Family of Watches

News

Introducing Rolex’s All New 2020 Submariner Family of Watches

Perfecting the Perfect Dive Watch

Part 1: The Watches

It is the year of our Lord Twenty O Six. And upon this day, the first of September, Rolex has unveiled a subtle yet significant evolution to its most iconic model, the Submariner. A watch that is inextricably linked with cinema, worn by some of the most iconic men and women on earth, and has played a role in shaping human history since its launch, in 1953.

What is important to understand is that each time Rolex presents a new version of the Submariner, or any of their near mythological timepieces, it does not do this for the sake of creating novelty. Quite the opposite, each time Rolex launches a new model it forges the next link in an ongoing evolutionary process, characterized by steady improvement to every single dimension of that watch. It does so to incrementally advance every aspect of its timepieces solidifying them as the most reliable and best executed luxury sports watches on the planet.

Today as we look at the all-new Submariner family, comprising of the No-Date Reference 124060, which replaces the 114060, introduced back in 2012, and the Reference 126610, which replaces the revered 116610, launched back in 2010. We will take a look at the details of these watches from the perspective of its case, dial, bezel, movement and bracelet and how they represent functional improvements in the Submariner, all in aid of Rolex’s perennial quest to perfect the already perfect dive watch.

The 2020 Oyster Perpetual Submariner with date on the left, the ref. 126610 and the no-date ref. 124060 on the right in Oystersteel (©Revolution)

The New 41mm Case

As you have probably just experienced when you saw the statistic “41mm”, initially a wave of apprehension swept through the Revolution office when we first learned that Rolex was increasing the size of the seemingly perfect 116610 case by 1 millimeter. We immediately remarked, “But everyone is going to more classic proportions, why is Rolex making the Submariner bigger.” But rest assured that increase in size is purely a paper statistic. Because the case of the new 124060 and the 126610 actually feels smaller, slimmer and more elegant than its predecessor.

A side by side comparison of the 2020 ref. 126610 with the outgoing 2010 ref. 116610 both in Oystersteel; at 41mm the new Submariner case represents a marginal increase in size from its predecessors 40 mm in diameter and is still a full 2mm smaller than the 43mm diameter of its deep saturation dive sibling the Sea-Dweller. (©Revolution)

That’s thanks to a subtle but complete redesign of the case profile of the watch, characterized by two important things. For the “Maxi” style crown guards, these have been reduced significantly in size so that while they still offer the same function of protecting the crown, the area around the crown feels quite a bit less chunky. Second and equally importantly the new case lugs tapers more sharply towards their junction with the bracelet making the case feel svelte and dynamic.

The 2020 ref. 126610 case on the left showing noticeably slighter crown guards when compared with those of the outgoing 2010 ref. 116610's (©Revolution)

The crown is of the Triplock variety launched by Rolex in 1970 to equip the deep diving Sea-Dweller model and that features three sealed zones based on two gaskets within the winding tube and one just under the crown. The Triplock made it way to the Submariner in 1977, in the model 1680, where it has stayed ever since.

The 2020 no-date Oyster Perpetual Submariner ref. 124060 Oystersteel (904L steel) is fitted with the Triplock crown (©Revolution)

904L steel is received by Rolex and then scanned with an electron microscope for any imperfections, including any structural or surface defect. After inspection, the steel is re-melted in a vacuum to purify it and remove inclusions that would compromise its corrosion resistance. As you can see, Rolex’s focus is on creating watches that endure forever. Why do other brands not use 904L? Because it is much harder to machine and requires special tools to do so.

The very first Rolex Submariner model to use this material, which Rolex refers to as Oystersteel, is the reference 168000, a transitional model from 1987 that uses the same movement and dial as the 16800, made from 1979-1987 but the case from the 16610 which was launched in 1988. By 2003 all Rolex steel watches were using 904L based Oystersteel.

The Maxi Dial

The 2020 no-date Oyster Perpetual Submariner ref. 124060 has a Maxi-style dial with its Chromalight lume contained within applied white gold (©Revolution)

The dials of the new 124060 and 126610 Submariners are gloss dials with applied white gold luminous indexes. They feature slightly larger luminous plots, as well as hands, to aid in visibility particularly underwater than pre-2003 watches and are referred to as Maxi Dials.

Reference 5512 and 5513 were the first Rolex Submariners to feature Maxi Dials in some iterations. These were largely matte dials that had large luminous indexes painted directly onto them. The first Submariner to feature a gloss dial with applied white gold indexes filled with luminous paint was the 16800, starting in 1984, a feature that would be carried over to the 16610 Submariner Date launched in 1999 and the 14060 Submariner No Date launched in 1989. But the first modern Maxi Dial with oversized applied markers and hands on a gloss dial, appeared on the famous Kermit or 16610LV made from 2003-2010. This Maxi Dial was then carried over to the 116610 introduced in 2010 and remains with us today.

Chromalight

From the beginning, the Submariner is a model that required perfect visibility even in the low light conditions underwater. As such, Rolex has used various luminous compounds from radium to tritium to Luminova to create luminous hands and indexes for its sports watches.

Today, while the majority of other watch brands use SuperLuminova to create its luminous indexes, Rolex launched Chromalight back in 2008 with the creation of the Sea-Dweller Deep Sea. Chromalight glows blue in the dark, as opposed to the green of SuperLuminova and instead of glowing very bright and then quickly fading away, it features a much more stable luminous intensity which lasts much longer than conventional alternatives. The 124060 and the 126610 both use Chromalight treated indexes and hands to offer luminous indications that remain bright, more consistently, over a longer duration than most other watches.

In 2008, Rolex launched the Sea-Dweller DEEPSEA ref. 116660, which featured Chromalight as Rolex's choice of lume material for the first time; Chromalight stands apart from the industry standard, SuperLuminova with its blue glow as opposed to the latter's green glow

The 2020 no-date Oyster Perpetual Submariner ref. 124060 has a Maxi-style dial with its Chromalight lume contained within applied white gold

The Cerachrom Bezel

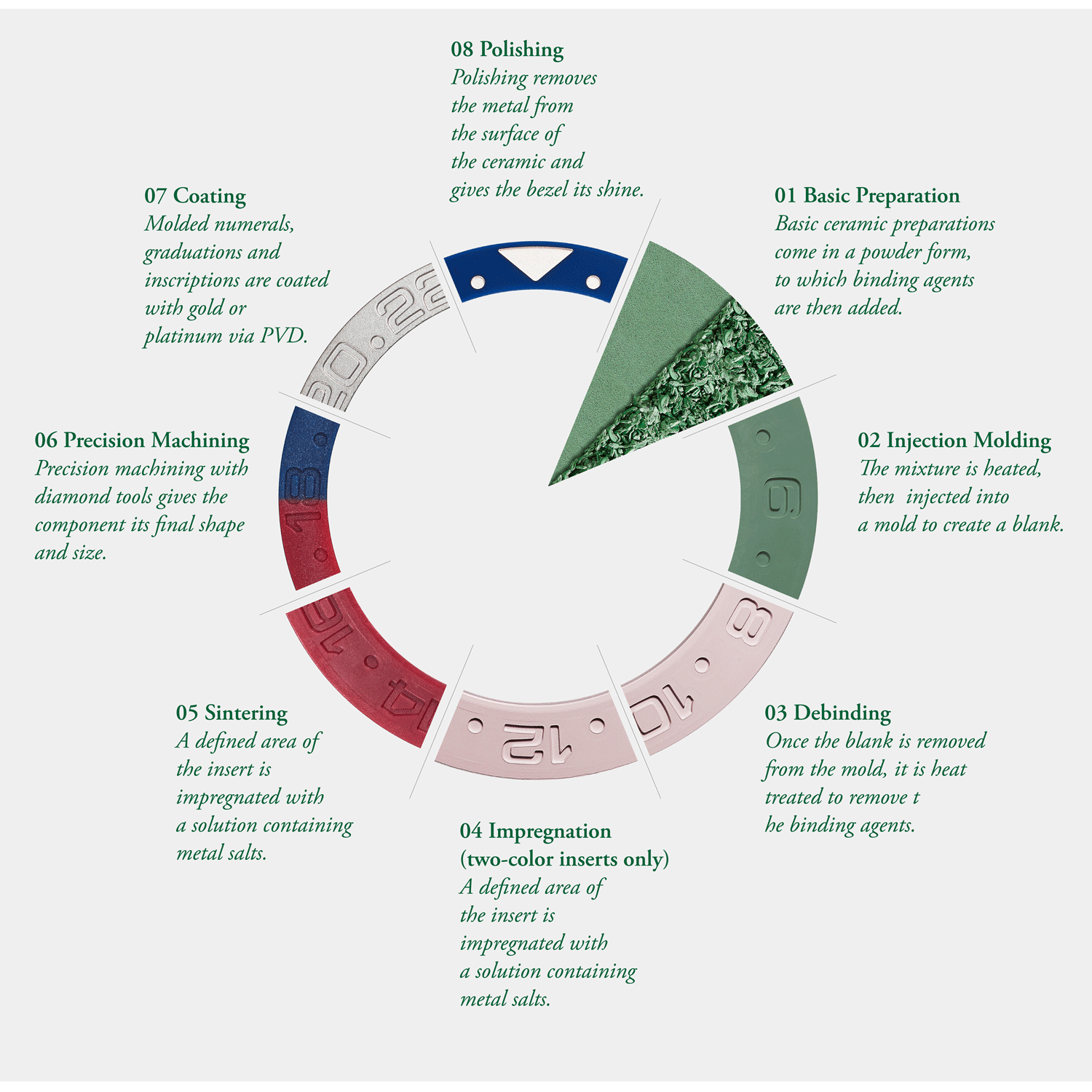

Like their predecessors, the 124060 and the 126610 Submariners use Cerachrom ceramic bezel inserts, which have now been adopted across all of Rolex’s sports watches. Why ceramic? Because ceramic has the highest Vickers rating for hardness for any material besides diamond. In its ongoing quest to create the most durable and reliable watches, in 2005 Rolex began its transition from aluminum bezel inserts for its various turning bezels to ceramic inserts.

Over the last 15 years Rolex has been at the forefront of ceramic technology creating some of the most beautiful colored bezel inserts for watches such as the white gold and blue bezel Submariner from 2008, the green dial and green bezel Submariner known as the “Hulk” from 2010 and of course the world’s first two color ceramic bezels blue and black for the model known as the “Batman” in 2013 and in blue and red for the GMT Master II model known as the “Pepsi” in 2014. Since its introduction in 2010 the Submariner Date 116610 and the Submariner No Date 114060 in 2012 both featured ceramic bezels.

A view of the sheer breadth of colors Rolex is able to achieve using their proprietary method of producing Cerachrome ceramic bezels

At the start basic ceramic preparations, are always in powder form; binding agents are added to the powder preparations, which include a mixture of zirconia and color pigments or alumina; the mixture is heated and then injected into molds at high pressure to create a blank; this step gives the piece its shape and molds the numerals, graduations and inscriptions

The negative voids for the indexes of these bezels are already present when they come out of the sintering process. Next a layer of PVD in platinum is applied for white text or gold for gold colored text. Then the entire surface of the bezel is diamond polished to remove the excess PVD material and also to render a high gloss finish to the bezel.

A step by step breakdown of Rolex's Cerachrome production process

Each Cerachrom bezel insert takes 40 hours to manufacture. In addition to a being virtually impervious to scratches, it is also not affected by UV light and will therefore never fade in color, indeed its vibrancy will endure forever.

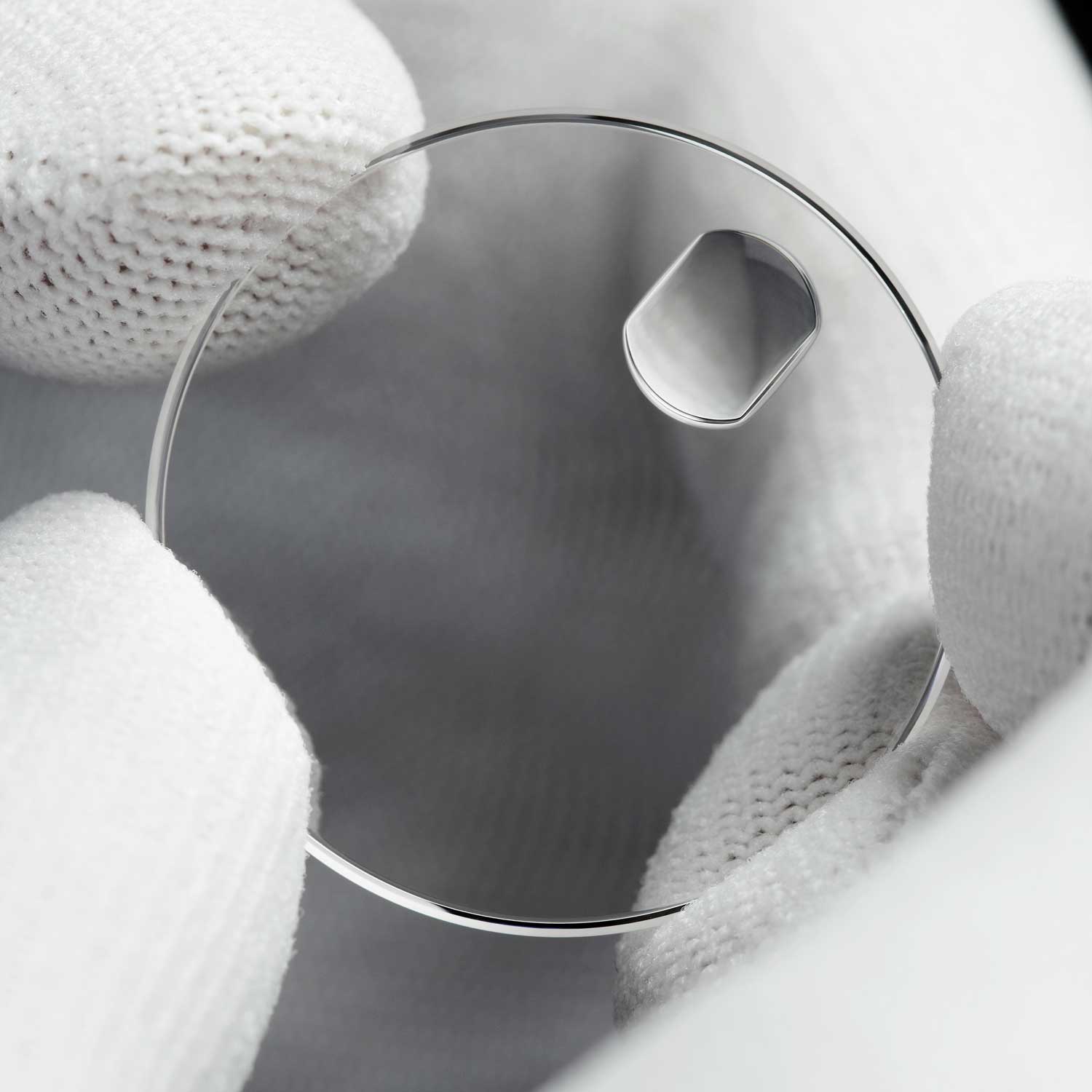

Sapphire Crystal

It’s funny no one ever really talks about Sapphire crystal in sport watches and the immense advantage they offer. While today Sapphire crystal has become the industry norm, it is important to understand that Rolex was a pioneer in the use of sapphire crystal in their watches.

Sapphire crystal is grown from monocrystalline aluminum oxide. It is far more scratch and shatter resistant than mineral glass and has a Mohs scale hardness of 9, which is exceeded only by diamond, with a Mohs scale hardness of 10.

While a small handful of high luxury watches had begun to adopt sapphire crystal in the 70’s (notably AP with the Royal Oak in 1972), Rolex was the first brand to adopt sapphire over acrylic crystals for its sport range of watches. The integration of sapphire crystals at Rolex began with Beta 21 Quartz watch reference 5100 in 1970, then made its way to the reference 1530 Date watch in 1975, to the Oyster Quartz in 1977, to the Day-Date in 1978 to the Sea-Dweller in 16660 in 1978 and then to the Submariner, namely model 16800, in 1979.

The first Submariner to use a sapphire crystal was the 1979 ref. 16800, which also allowed the watch its new 300m depth rating

Glidelock Bracelet

Since the creation of the Submariner watch back in 1953, it has always been synonymous with the Rolex Oyster link bracelet. It has followed an evolutionary process in keeping with the advances represented by the watch head.

The manufacturing process has gone from riveted (1953), to folded (1967), to folded with solid end links to where it is today with solid links (1975). Similarly, the clasp of the Submariner has also changed with time. In 1969 the Submariner was the first Rolex to receive an extra secure lock on top of the folded clasp system, which also hid a simple but extremely efficient extra link for expansion over a dive suit.

All of the new Submariner range of watches feature Rolex’s Glidelock deployant clasp. The first watch with the incredible Glidelock system for rapidly adjusting the length of your bracelet by up to 2cm was the Rolex DEEPSEA Sea-Dweller, launched in 2008. With this system by lifting up the tip of the clasp that normally fits under the safety lock, you release the bracelet where it is fixed inside of the deployant. Then you can glide the bracelet to make it either smaller of larger by up to 2cm in 2mm increments.

The Oysterlock safety clasp on the The Glidelock extension system found on the bracelet of the 2020 Oyster Perpetual Submariner (©Revolution)

The Glidelock extension system found on the bracelet of the 2020 Oyster Perpetual Submariner

Oyster Perpetual Calibres 3230 & 3235

Increasing water resistance and innovations to the case, dial and bracelet represent only part of Rolex’s focus on technical advancement and progress over the 67 year evolution of the Rolex Submariner.

Over the history of the model reliability, shock resistance and accuracy in time keeping has always been of paramount importance and this comes down to the movement driving the Submariner Date and No Date watches. The movements that have powered the Submariner including the 1575, 3035, 3135, with Date, and the 3000, 3130, without Date, are some of the most beloved in watchmaking history.

By 2010, for the Submariner Date 116610 and by 2012 for the Submariner No Date 114060, Rolex had switched over to truly excellent movements, respectively the 3135 and 3130 calibres, featuring the Parachrom hairspring. Like all 31-series movements, they beat at 4Hz, or 28,800vph, (this vibrational speed was introduced with the 3035, in 1981, in the reference 16800).

They featured a free sprung balance with Microstella adjustments screws, which has been a Rolex calling card since the 30-series movements. They both featured full transverse balance bridges as opposed to balance cocks in the previous 30-series movements, and overcoil hairsprings for more concentric breathing, as opposed to flat spirals. Further, these hairsprings were laser welded to the stud, while hairsprings in the 30-series of movements were glued. Being made from Parachrom these hairsprings were not susceptible the erosive effects of magnetism.

So how do you improve on an already impressive movement? In 2015, Rolex responded with the launch of the Calibre 3235, an automatic movement with date, which represented an incredible leap forward in terms of performance in terms of accuracy, reliability, shock resistance and power reserve. This movement would feature 90 percent new components, an increase of power reserve from 50 to 70 hours, a proprietary escapement that was 15 percent more efficient and 14 patents.

Oyster Perpetual Calibre 3235 was first introduced with the 2015 DateJust Pearl Master 39 (©Revolution)

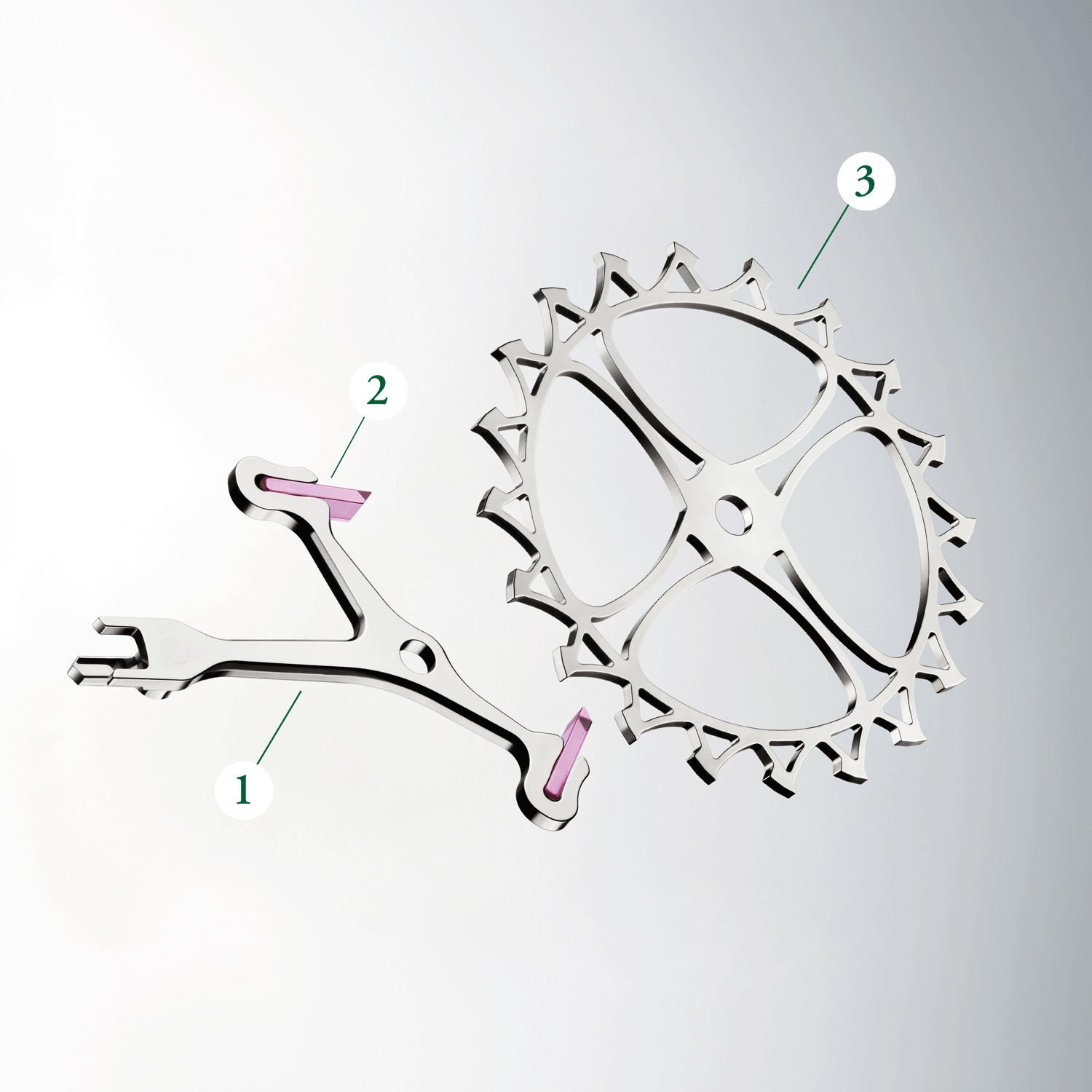

Chronergy Escapement

The vast majority of the Swiss watch industry relies on the tried and tested Swiss anchor escapement. This escapement however has two vulnerabilities. The first is that the way in which the pallets contact the sliding face of the escapement wheel results in sliding friction. Second is it generally manufactured in traditional materials it is susceptible to becoming magnetized.

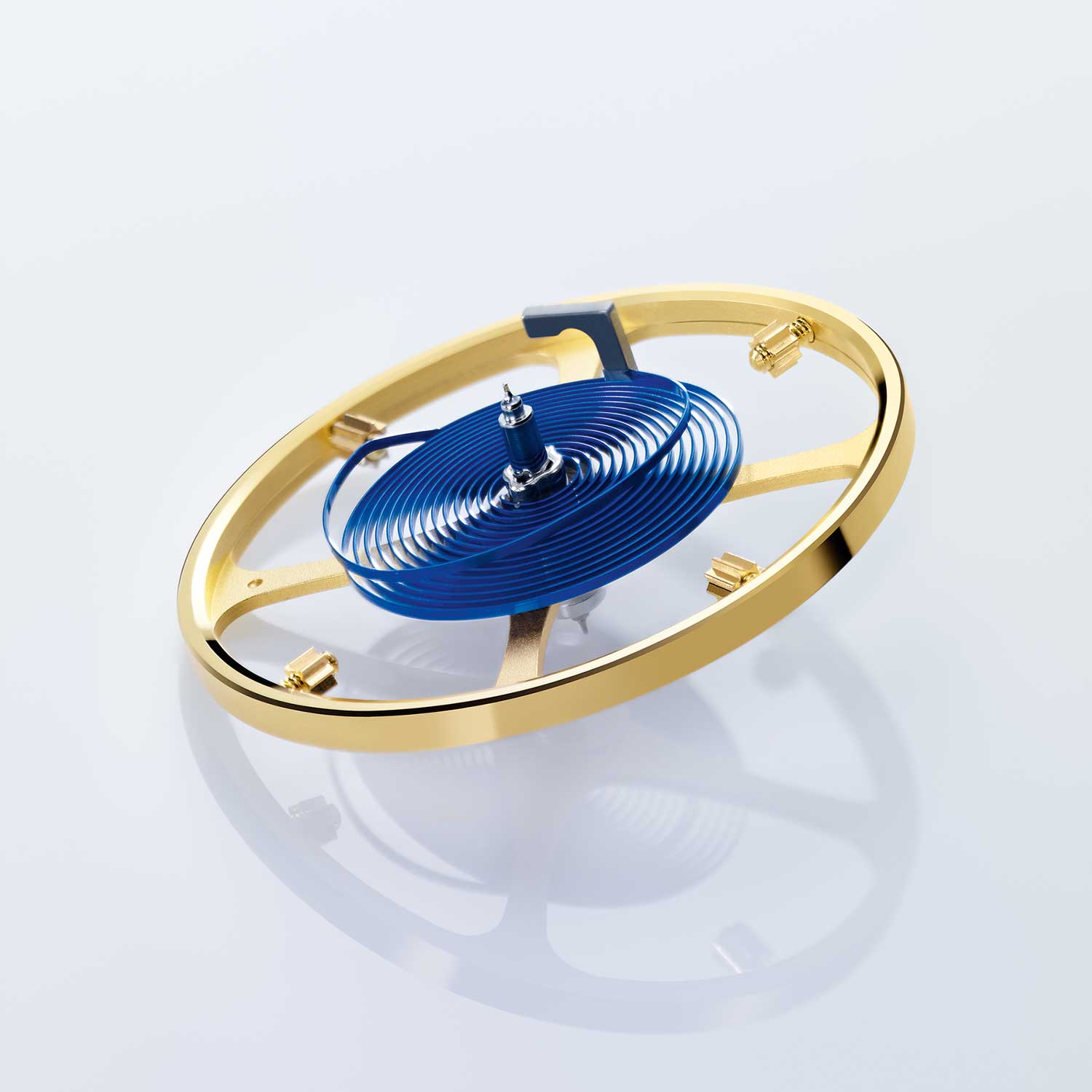

The Rolex Chronergy Escapement

Parachrom Hairspring

The Calibres 3235 and 3230 use hairsprings created from a material patented by Rolex called Parachrom. These hairsprings are easy to spot, thanks to their unique blue color.

Insensitive to magnetic fields, the Rolex Parachrom hairspring offers great stability against temperature variations and is 10 times more precise than a traditional hairspring in case of shocks.

The final spring (1 foot of Parachrom makes 10,000 springs) is 150 microns wide and 45 microns high. It is coiled then separated by hand and has a Phillips terminal curve made by a special machine created by Rolex before being fixed to a balance wheel, where it will beat in your watch — shrugging off shock, temperature variation and all forms of inclemency with total bad-ass reliability. Parachrom has the additional significant advantages of not being affected by magnetism and is up to 10 times more shock resistant than other metal hairsprings.

The first Parachrom hairsprings were placed in the in-house vertical clutch chronograph calibre 4130 for the Daytona back in 2000. The Parachrom hairspring was also used in the 31-series movements, such as the caliber 3186 used for the GMT Master II and was carried over to the 32-series of movements.

Increased 70-Hour Power Reserve

Rolex has also increased the power reserve of the new movements first through the gain in 15 percent efficiency thanks to the new Chronergy escapement. The escape wheel is skeletonized and despite having more surface area is lighter and has less inertia and the escapement design produces less sliding friction. At the same time Rolex reduced the thickness of the barrel walls by 50 percent meaning the mainspring could be longer and hold 10 more hours of charge for a total of 70 hours.

Full Traversing Balance Bridge

This implementation began with the 3130 and the 3135 movements. The 3130 made its appearance in the No Date Submariner reference 14060M, from 1987, while the 3135 made its appearance in the 16610, from 1988. As opposed to the 3000 and the 3035 calibres these movements had full traversing balance bridges fixed on both sides.

The 3230 and 3235 have in-house designed Paraflex shock absorbers that bisect the jewels diagonally and retain it with a rectangular frame. These shock absorbers were designed and patented by Rolex in 2005, and aid in increasing shock resistance by an incredible 50 percent. They are also much easier to service.

There is, also, yellow screw on the balance. This helps to maintain the position of the traversing balance bridge and keeps it stable. It can be used to adjust the height of the bridge n order to ensure the calibre’s chronometric performance.

The Full Traversing Balance Bridge implementation of the Oyster Perpetual Calibre 3235 with the additional yellow screw that aids in its fine adjustment

Other Improvements

Other improvements to the 3200 series movements include a friction fit balance staff, a monobloc one-piece automatic rotor, mounted on ceramic ball bearing for more efficient winding — just to throw a few extras in there.

The Rolex Superlative Chronometer Test

Each 32-series movement undergoes Rolex’s in-house Superlative Chronometer test. As opposed to other tests such as COSC, which only tests movements (the criteria have changed recently) Rolex prefers to test entire watches. Further while COSC certification requires movements to test within -4/+6 seconds maximum deviation per day, Rolex’s criteria is much stricter at -2/+2 seconds. Rolex is the only one of two sports watch brands that subjects its watches to a double certification process.

Since 2018, Rolex has demarcated all of their Superlative Chronometer rated watches with a new coronet printed between the words "Swiss Made" at 6 o'clock; this now also appears on the dial of the 2020 family of Submariner watches (©Revolution)

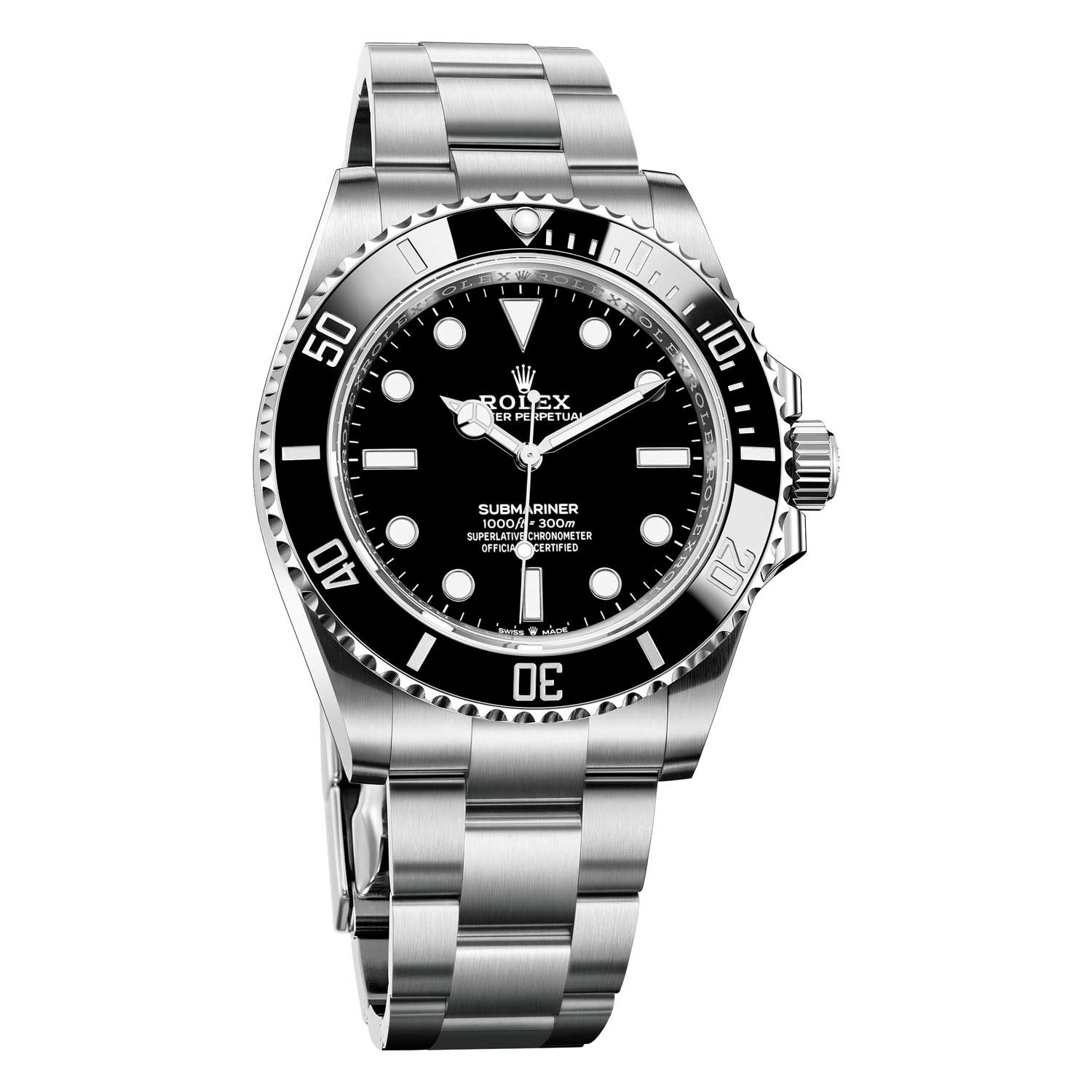

Reference 124060

Movement

Self-winding Calibre 3230 Manufacture Rolex; hours, minutes and centre seconds; −2 /+2 sec/day Superlative Chronometer (COSC + Rolex certification after casing); 70-hour power reserve

Case

41mm in Oystersteel (904L stainless steel); unidirectional black Cerachrom bezel; water-resistant to 300m

Bracelet

Oystersteel bracelet with Oysterlock folding safety clasp and Rolex Glidelock extension system

Price

USD 8,100

[/td_block_text_with_title]

The 2020 Oyster Perpetual Submariner in Oystersteel ref. 124060

Reference 126610

Movement

Self-winding Calibre 3235 Manufacture Rolex; hours, minutes and centre seconds; date; −2 /+2 sec/day Superlative Chronometer (COSC + Rolex certification after casing); 70-hour power reserve

Case

41mm in Oystersteel (904L stainless steel); unidirectional black Cerachrom bezel; water-resistant to 300m

Bracelet

Oystersteel bracelet with Oysterlock folding safety clasp and Rolex Glidelock extension system

Price

USD 9,150

The 2020 Oyster Perpetual Submariner Date in Oystersteel ref. 126610 (©Revolution)

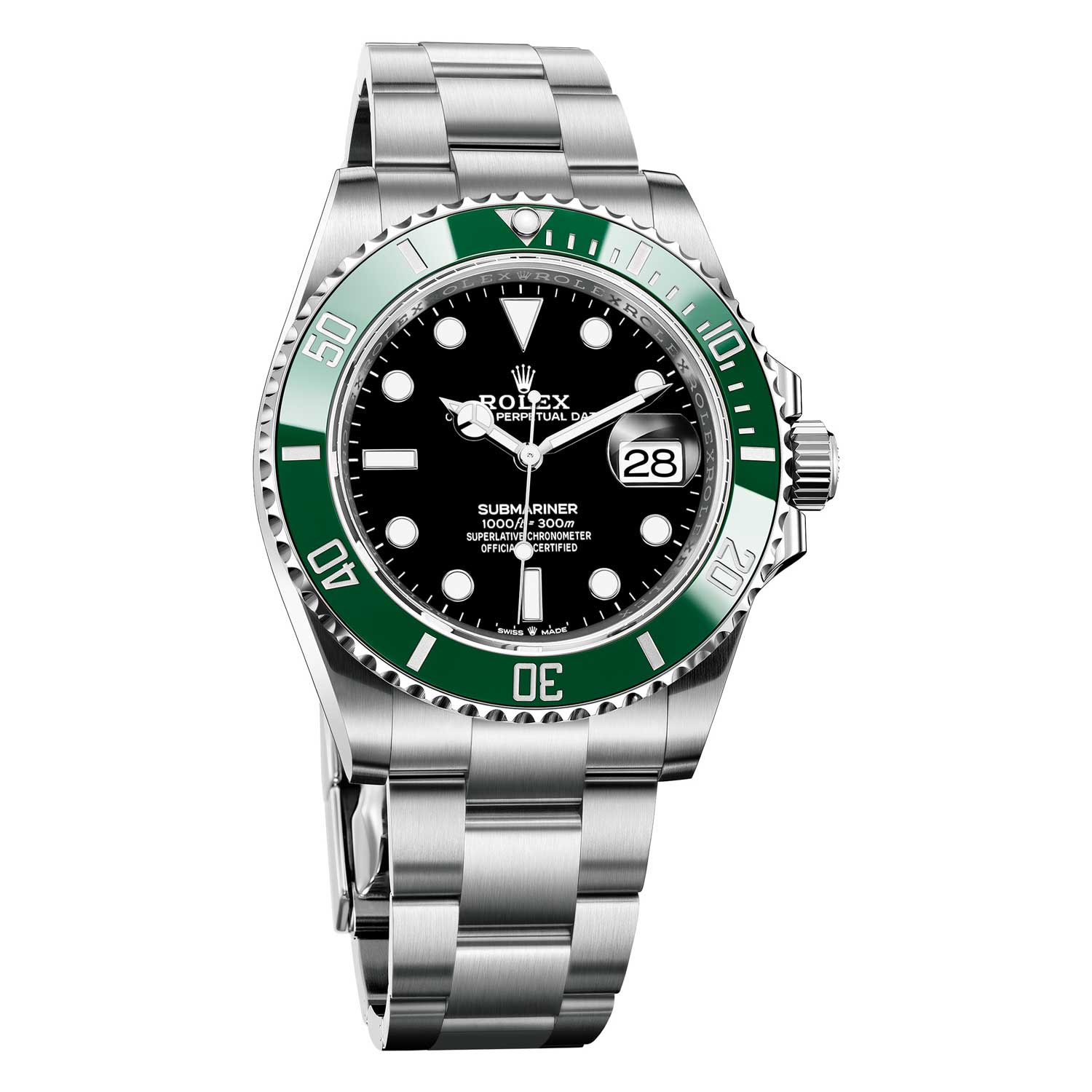

Reference 126610LV

Movement

Self-winding Calibre 3235 Manufacture Rolex; hours, minutes and centre seconds; date; −2 /+2 sec/day Superlative Chronometer (COSC + Rolex certification after casing); 70-hour power reserve

Case

41mm in Oystersteel (904L stainless steel); unidirectional green Cerachrom bezel; water-resistant to 300m

Bracelet

Oystersteel bracelet with Oysterlock folding safety clasp and Rolex Glidelock extension system

Price

USD 9,550

The 2020 Oyster Perpetual Submariner Date in Oystersteel ref. 126610LV

Reference 126613 LB

Movement

Self-winding Calibre 3235 Manufacture Rolex; hours, minutes and centre seconds; date; −2 /+2 sec/day Superlative Chronometer (COSC + Rolex certification after casing); 70-hour power reserve

Case

41mm in Oystersteel (904L stainless steel) and 18ct yellow gold (yellow Rolesor); unidirectional blue Cerachrom bezel; water-resistant to 300m

Bracelet

Oystersteel and 18ct yellow gold (yellow Rolesor) bracelet with Oysterlock folding safety clasp and Rolex Glidelock extension system

Price

USD 14,300

The 2020 Oyster Perpetual Submariner Date in Oystersteel and 18ct yellow gold ref. 126613LB

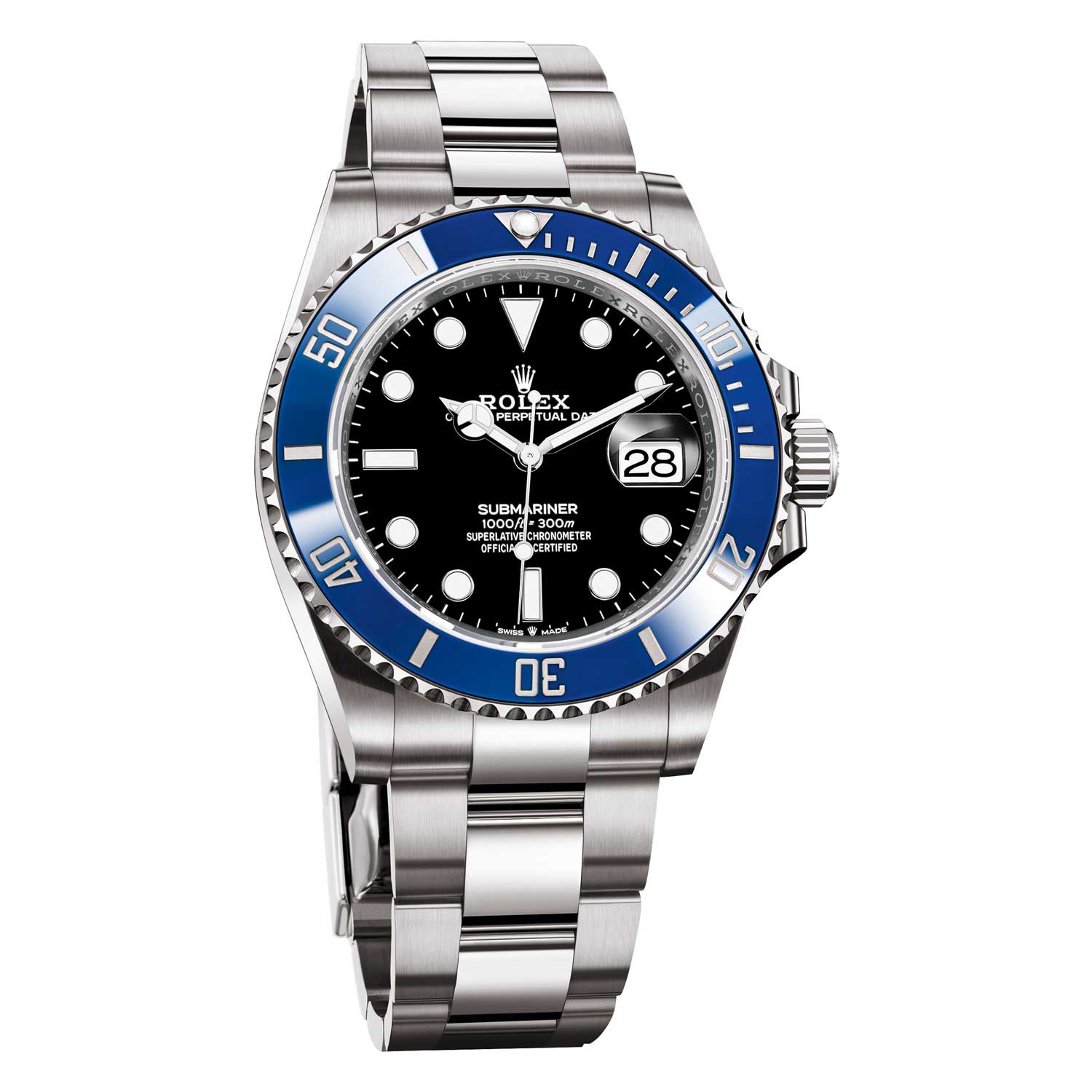

Reference 126619 LB

Movement

Self-winding Calibre 3235 Manufacture Rolex; hours, minutes and centre seconds; date; −2 /+2 sec/day Superlative Chronometer (COSC + Rolex certification after casing); 70-hour power reserve

Case

41mm in 18ct white gold; unidirectional blue Cerachrom bezel; water-resistant to 300m

Bracelet

18ct white gold bracelet with Oysterlock folding safety clasp and Rolex Glidelock extension system

Price

USD 39,650

The 2020 Oyster Perpetual Submariner Date in 18ct white gold ref. 126619LB