Grand Seiko

Introducing the Grand Seiko T0 (T-Zero) Constant-Force Tourbillon

Grand Seiko

Introducing the Grand Seiko T0 (T-Zero) Constant-Force Tourbillon

Read more about the history of Grand Seiko, here.

A masterwork of the Grand Seiko designers’ inventiveness, the T0 combines a fully integrated constant force mechanism (a.k.a. remontoire) and tourbillon on the same axis for the very first time. The Grand Seiko Studio Shizukuishi was allowed to dream without the constraints of considering production capabilities, bringing about the T0 Constant-force Tourbillon concept while inspiring essential parts of the Caliber 9SA5, the high-accuracy, long-lasting performance movement released earlier this year. Developed simultaneously in secret, the all-consuming process allowed for the conception of two entirely new movements designed entirely from the ground up.

So why is this T0 Constant-force Tourbillon so significant? Let’s try to break it down.

Mechanical watches get their power from the unwinding force of a mainspring. This mainspring slowly loses energy as it unwinds. This accuracy has improved for extended hours due to advancements in watchmaking (i.e., Grand Seiko’s Calibre 9SA5). Ideally, torque (the twisting force that causes rotation) should be the same fully wound or unwound. Keeping torque stable is vital for maintaining timepiece accuracy. The constant force mechanism of the T0 is a groundbreaking way to ensure the stability of this torque.

When constant force gets placed close to a mainspring, the mainspring’s unwinding power is easier to control. However, the torque becomes irregular, and the efficiency of the watch becomes uneven. If it’s placed closer to the balance, energy becomes more stable, but the torque is harder to control—a delicate trade-off, nearly impossible to have it both ways. Here a stable system was developed, placing the constant force as close to the balance as possible. This is the part where gravity comes into play with the addition of the tourbillon.

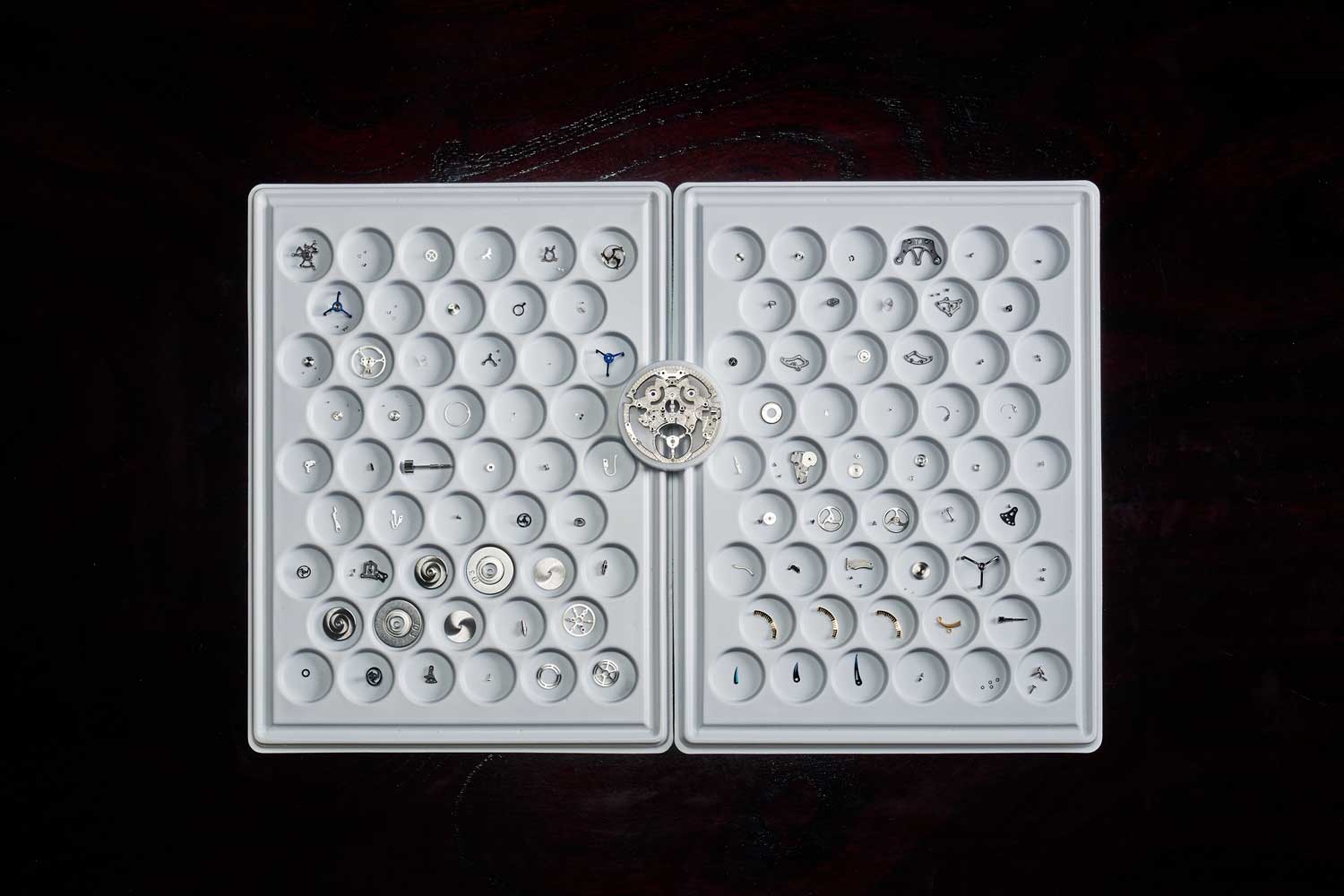

T0 Constant-force Tourbillon movement broken down into its minuscule parts

Additional improvements were added based on mechanical achievements from earlier innovations like the Calibre 9S65– the mainspring, wheel trains, escapement, balance, setting lever, and yoke. The 9SA5 provided a free-sprung balance with a regulator and high beat technology boasting 28,800 vibrations/hour. A prototype tested revealed that gravity’s impact was reduced to one-tenth or less due to the tourbillon, and high-accuracy was maintained for 50 hours out of 72 hours due to the constant force. The combination of high frequency with a free-sprung balance would significantly increase the accuracy when wearing a watch – the T0 backs this up with a real movement.

A side view of the Grand Seiko T0 (T-Zero) Constant-Force Tourbillon

The back of the Grand Seiko T0 (T-Zero) Constant-Force Tourbillon movement